WHAT WE DO

![]()

![]() WHAT WE DO

WHAT WE DO![]() Tunnels

Tunnels

Tunnels

as a part or complete subways, highways, railways and waterways etc. since its establishment in 1996.

ESCO has a strong competitive edge, and can clearly demonstrate its expertise and intensive experience in

tunnel designs demonstrated by the fact that two-thirds of all projects executed by ESCO were the results

of design competitions for design-build projects or alternative designs for underground works.

Long Tunnels

-

Subways are normally considered as long tunnels no matter what construction methods are employed: mined or cut-and-cover tunneling. Many other long tunnels were designed by ESCO including highway, railway and waterway tunnels etc.

Appropriate ventilation systems for normal and emergency hours:

The layout shown above is one of the highway tunnels designed by ESCO. The technical issues and solutions were;

Longitudinal ventilation system with two vertical ventilation shafts (H = 277m, D = 13.4m)

Installation of disaster prevention facilities: safety zone, high pressure water mist fire protection system, etc.Construction without delay: planning and execution of optimal excavation method and sequences

(L = 11km, 4-lanes, max. D = 512m)

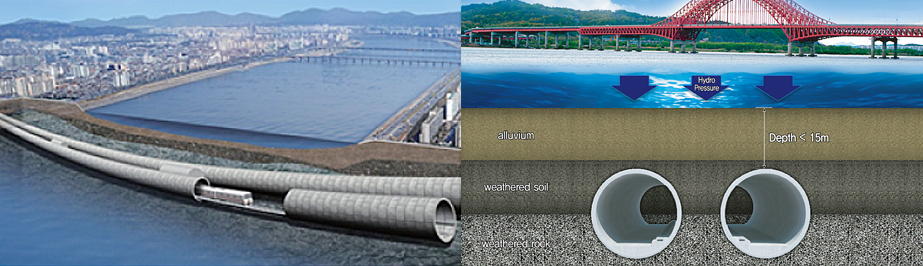

Undersea or Underwater Tunnels

-

Undersea or underwater tunneling is one of the most challenging tasks for tunnel designers. For successful construction,

Selection of an appropriate TBM machine suitable for the hydro-geological conditions;

comprehensive analyses of all kinds of feasible solutions with a given set of geological data need to be carried out before the final selection of solution. ESCO’s engineers have substantial experience in these technically demanding projects.

The layout shown above is one of the underwater tunnels designed by ESCO and its technical issues were:

Shallow ground coverage (D < 15m) with mixed subsurface ground composed of weathered soils and weathered rocks;

high hydrostatic pressure (Pmax = 4MPa)

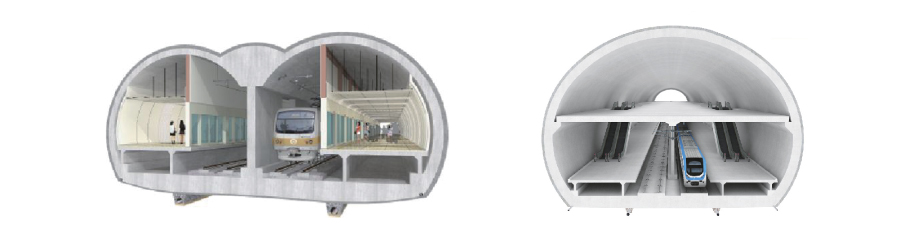

Large Cross-Section Tunnels

-

Generally, subway tunnels are constructed as near to the surface as possible.

This is one of the primary reasons why the subway tunnels frequently encounter poor geological conditions during the construction.

It is obviously a challenging task if large cross-sectional tunnels like station tunnels have to be constructed with bored methods

in adverse ground conditions. ESCO’s engineers have substantial experience in these types of technically demanding projects.

The selection of excavation methods, suitable support and waterproofing systems are major technical issues to be managed carefully.

Tunnel Boring Machine (TBM) Tunnels

-

-

Demand on mechanized tunneling is rapidly increasing throughout the world nowadays. The Korean construction market is not an exception. ESCO’s engineers are quite familiar with the mechanized tunneling as well. We fully understand about the TBM mechanism, both open and shield, and have the capability to assess and deal with any possible trouble anticipated during construction stage for

any given set of geological data. The layout shown above is one of projects designed by ESCO driven with a TBM.

- WHO WE ARE

- About ESCO

- Organization

- History

- ESCO culture

- WHAT WE DO

- Tunnels

- Caverns

- Soft soil engineering

- Foundations & Slopes

- Research and Development

- Underground Safety Evaluation

- PROJECT

- Subway tunnels

- Railway tunnels

- Road tunnels

- Caverns

- Soft soil engineering

- Foundations

- Underground safety Evaluation

- Others

- NEWS

- Press

- ESCO Issue

- CONTACT US

- Careers

- Contact Info

KOR

KOR